Overview

Course video

Learn how to design and build with Fiber Reinforced Polymers (FRPs) - the new high-performance composite material in building and infrastructure projects.

Fiber Reinforced Polymers (FRPs) are a new material in structural engineering practice and architecture. Low weight and high durability make FRPs a promising solution for many applications.

If you want to start or progress the use of FRPs in your projects and need relevant knowledge and experience, this course is for you.

You will learn how to design and build with this new high-performance composite material increasingly used in building and infrastructure projects.

The course is designed for professionals who may include early-career and senior structural engineers, architects, consultants, reviewers, project managers and decision makers at investors and/or state institutions, who have experience with classical structural engineering materials.

What you'll learn

You will improve your career prospects by learning about manufacturing, durability, mechanical behavior and design guidelines. The course offers different learning outcomes depending on your background and professional interests.

After taking the course, structural engineers and architects will be able to:

- Exploit the advantages of FRPs with respect to traditional materials in infrastructure and building projects whilst being aware of the limitations that exist for specific applications.

- Make informed selections from the wide range of different FRP materials and production processes suited to a specific application.

- Deliver a realistic design for FRP structures.

- Perform design verification for simple to modestly complex structural members and joints between members.

- Use analytical and computational methods to analyze structural behavior and obtain results for design verifications.

Reviewers and project managers at state institutions or investors will be able to:

- Perform critical reviews of the applicability and implementation of FRP material in construction projects.

- Follow the construction process and recognize critical points in the projects that need special attention.

Consultants and decision makers will:

- Obtain clear insight into when to use FRP instead of classical building materials.

Benefits of using FRPs

- FRPs offer designers opportunities for innovative, free-form design;

- Construction companies can benefit from reducing the weight of a bridge deck for example and experience a snowball effect with reductions in the costs for foundations, lifting equipment, transportation, bearings, etc.;

- Infrastructure owners can make profits in the long term by investing in FRP structures which are corrosion and fatigue free and therefore exclude costly and time-consuming maintenance.

This course has been designed for a limited number of participants due to extensive and individual feedback. There are only 30 places available.

Details

FRPs in building and infrastructure

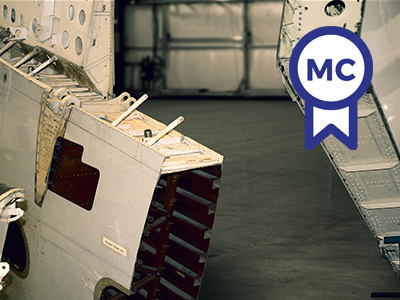

So far widespread use of FRP composites in buildings and infrastructure projects is held back by lack of knowledge and lack of clear design guidelines. In this course, co-created by TU Delft experts and industry partners, you will learn about engineering applications with FRPs in building and infrastructure development. There are more widely available courses about the use of composite materials in the field of aerospace engineering. But aspects and requirements such as scale, laminate composition, nature of loading, environment, life-span, production techniques and tolerances, quality control, inspection and maintenance are quite different in construction projects compared with aerospace and automotive applications.

(Re)design your project using FRP and receive personalized feedback

Throughout the course you will work with hands-on exercises. The exercises will include the option to bring your own case of a previous project to redesign using FRP. Design verifications will also be included. Feedback will consist of personal comment from the instructors and peer review from other participants. In this way, you will explore the possibilities of using FRPs for projects and in roles that are relevant for you.

Up-to-date academic developments will be used. Experiments and simulations performed by the instructors will provide a link between the theory and practice of material behavior.

The team at TU Delft and guest instructors have over 10 years of experience in design, review, research and education in fields such as bridges, structural mechanics, FRP composites and steel and hybrid structures.

Course Syllabus:

Module 1 – Introduction

Examples of applications (new-build, retrofitting), life-cycle assessment (LCA) results indicators, constituents of the composite material, rule of mixtures.

Module 2 – Structural design

Construction and assembly, developing an FRP solution, conceptual design, design of materials.

Module 3 – Mechanical behavior of the material

Orthotropic behavior, failure modes, simulation tool.

Module 4 – Specific behavior of the material

Durability, environment, production, robustness, FRP decks.

Module 5 – Design verifications

Design codes and recommendations, verification of cross sections and members, Verification of joints, finite element analysis (FEA) in design verifications.

Module 6 – Discussion of the designs and Wrap-up

Peer review with help of the instructors. Discussion of the assignments (cases).

Assessment & Assignments

There will be a group assignment related to conceptual design based on your own previous project:

- Conceptual design

- Preliminary design

- Input for the final design

Design verifications will be practiced through an individual assignment focusing on a generic case:

- Using of a simulation tool

- Design of a hollow beam

- Optimizing the layup

- Selection of safety factors

- Unity checks

- FEA (optional)

The third assignment will consist of peer review of other participants' work on the first two assignments. The final feedback will always be provided by the course instructors.

Contributing partners:

Royal HaskoningDHV, Chalmers University of Technology, Infracore Company, TNO, WMC Knowledge Centre, BiinC - Nederland, ALIANCYS AG.

Qualifications

Certificates

If you successfully complete this course you will earn a professional education certificate and you are eligible to receive 5.4 Continuing Education Units (CEUs).

Chartered Engineering Competences

All our online courses and programs have been matched to the competences determined by KIVI’s Competence Structure, a common frame of reference for everyone, across all disciplines, levels and roles.

These competences apply to this course:

- A1: Extend your theoretical knowledge of new and advancing technologies.

Admission

This course is primarily geared towards working professionals.

Prerequisites:

- Bachelor of Science or Engineering (BSc or BEng).

- Experience with structural engineering on professional level.

This course has been designed for a limited number of participants due to extensive and individual feedback. There are only 30 places available.

Contact

If you have any questions about this course or the TU Delft online learning environment, please visit our Help & Support page.